High Tensile Reclaim is a high quality reclaim manufactured for products requiring Higher Tensile Strength. It is a form of Natural Tyre Reclaim but with hugely enhanced Tensile Strength. High Tensile Reclaims help in enhancing the physical properties of the compound. It is mainly used in Conveyor Belts, Tyres & other Moulded products. We make High Tensile Reclaims from 6mpa Tensile up to 10mpa Tensile.

Reclaim with higher physical properties helps in retaining the properties of the compound. Higher dosage of reclaim will further reduce the cost of the compound.

Higher dosage of reclaim should increase the green tack of the compound.

ADVANTAGE

- Faster Mixing Cycle.

- Improved die swell.

- Reduction in consumption of electrical power due to nerve of compound & faster mixing cycle.

- Practically no reduction in hot air ageing properties

- Higher dosage of reclaim can be considered for the present level of physical properties

- Higher dosage of reclaim will further reduce the cost of the compound |

- Higher dosage of reclaim should increase the green tack of the compound.

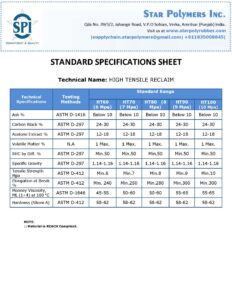

Technical Specifications | Testing Methods | Standard Range | ||||

HT60 | HT70 | HT80 | HT90 | HT100 | ||

| Ash % | ASTM D-1416 | Below 10 | Below 10 | Below 10 | Below 10 | Below 10 |

| Carbon Black % | ASTM D-297 | 24-30 | 24-30 | 24-30 | 24-30 | 24-30 |

| Acetone Extract % | ASTM D-297 | 12-18 | 12-18 | 12-18 | 12-18 | 12-18 |

| Volatile Matter % | N.A | 1 Max. | 1 Max. | 1 Max. | 1 Max. | 1 Max. |

| RHC by Diff. % | ASTM D-297 | Min.50 | Min.50 | Min.50 | Min.50 | Min.50 |

| Specific Gravity | ASTM D-297 | 1.14-1.16 | 1.14-1.16 | 1.14-1.16 | 1.14-1.16 | 1.14-1.16 |

| Tensile Strength Mpa | ASTM D-412 | Min.6 | Min.7 | Min.8 | Min.9 | Min.10 |

| Elongation at Break % | ASTM D-412 | Min. 240 | Min.250 | Min.280 | Min.300 | Min.300 |

| Mooney Viscosity, ML (1+4) at 100 oC | ASTM D-1646 | 45-55 | 50-60 | 50-60 | 55-65 | 55-65 |

| Hardness (Shore A) | ASTM D-412 | 58-62 | 58-62 | 58-62 | 58-62 | 58-62 |